-

Customer

KIA Motors, a prestigious and longstanding Korean automotive brand founded in 1944, is renowned for manufacturing vehicles that are perfectly adapted to various country operation conditions, catering to diverse needs and preferences.

-

Goals

- Decrease the life cycle of the employee time tracking process;

- Reduce financial expenditure on expendable materials.

-

Tasks

- Reduce labor costs associated with the time tracking process;

- Transition from paper to electronic media.

-

Solution

Assign functions such as notification, transfer, and storage within the employee time tracking process to a computer program. Automate the employee time tracking process.

-

Description

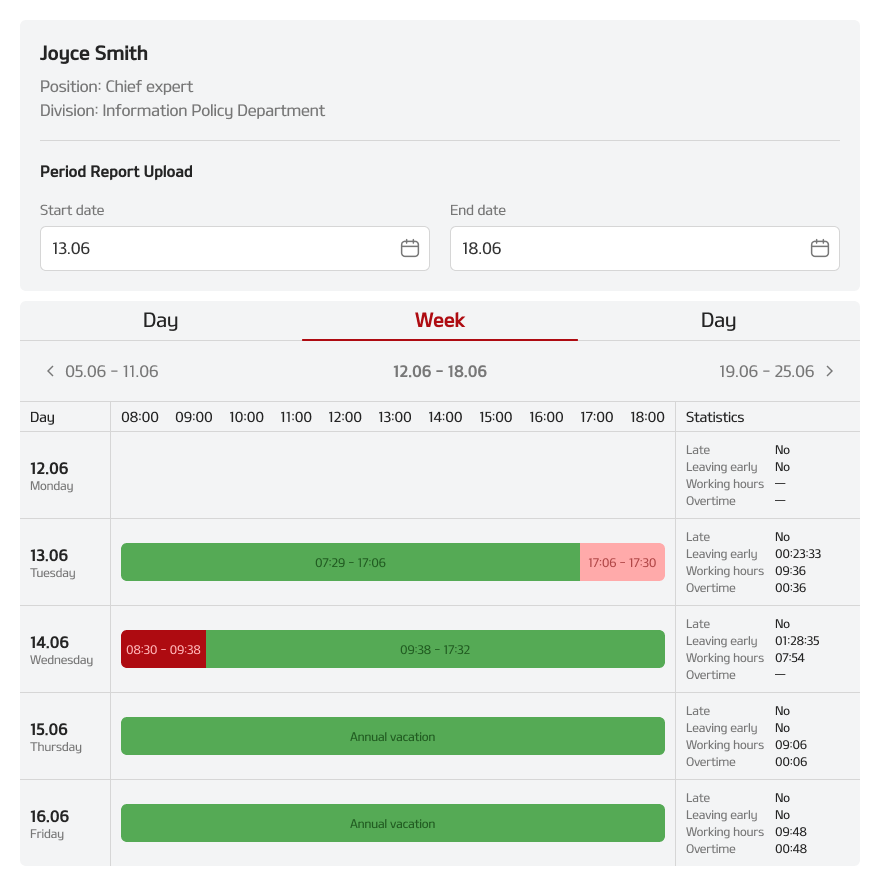

The "Attendance Log" module has been developed for the corporate portal. Each employee is assigned a "Key Code" in the system, which serves as their passcode at the checkpoint.

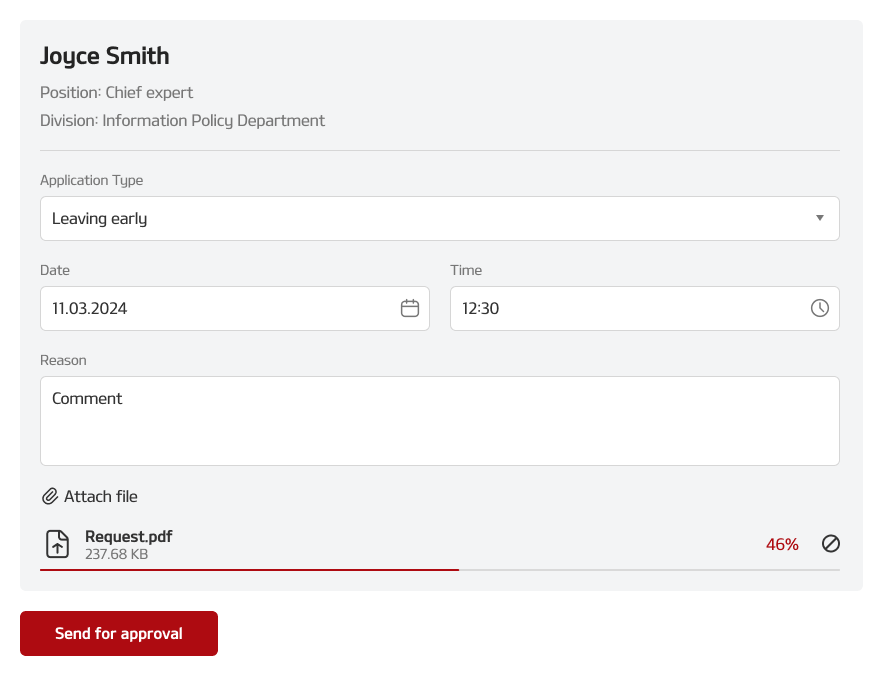

In case an employee is late or leaves early, the information is recorded in the Attendance Log. This log includes:

- Work time;

- Delays;

- Early leaving;

- Notified in advance;

- Notified by fact.

Additionally, the module allows employees to coordinate their departures or delays with their supervisors.

-

Reports

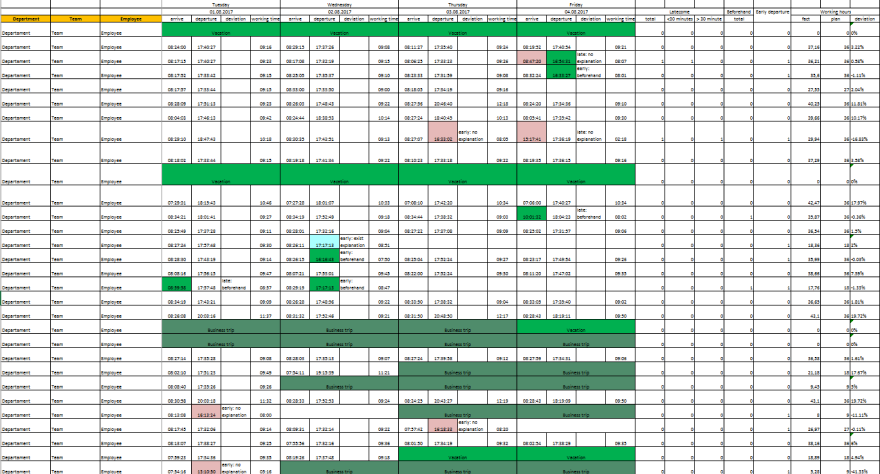

The system generates an excel-based attendance report for each employee, which is sent to both the employee and their supervisor either weekly or monthly.

The report includes:

- Employee’s working hours;

- Account of business trips;

- Account of vacations;

- Statistics on delays;

- Statistics on early departures;

- Deviations between actual and planned working hours.

The system enables the uploading of attendance reports for any specified period.

Additionally, a departmental attendance log has been developed for supervisors. This log displays the attendance details of all employees within the department and allows for the uploading of reports in Excel format.

-

Results

Financial expenditures on expendable materials such as paper and printer ink have been eliminated.

The life cycle of the employee time tracking process has been reduced by 80%.

LINE it!

LINE it!